How are manufacturers in different regions handling tariff uncertainty?

Experiences vary by region, but many say they're trying to avoid passing on tariff costs to their consumers.

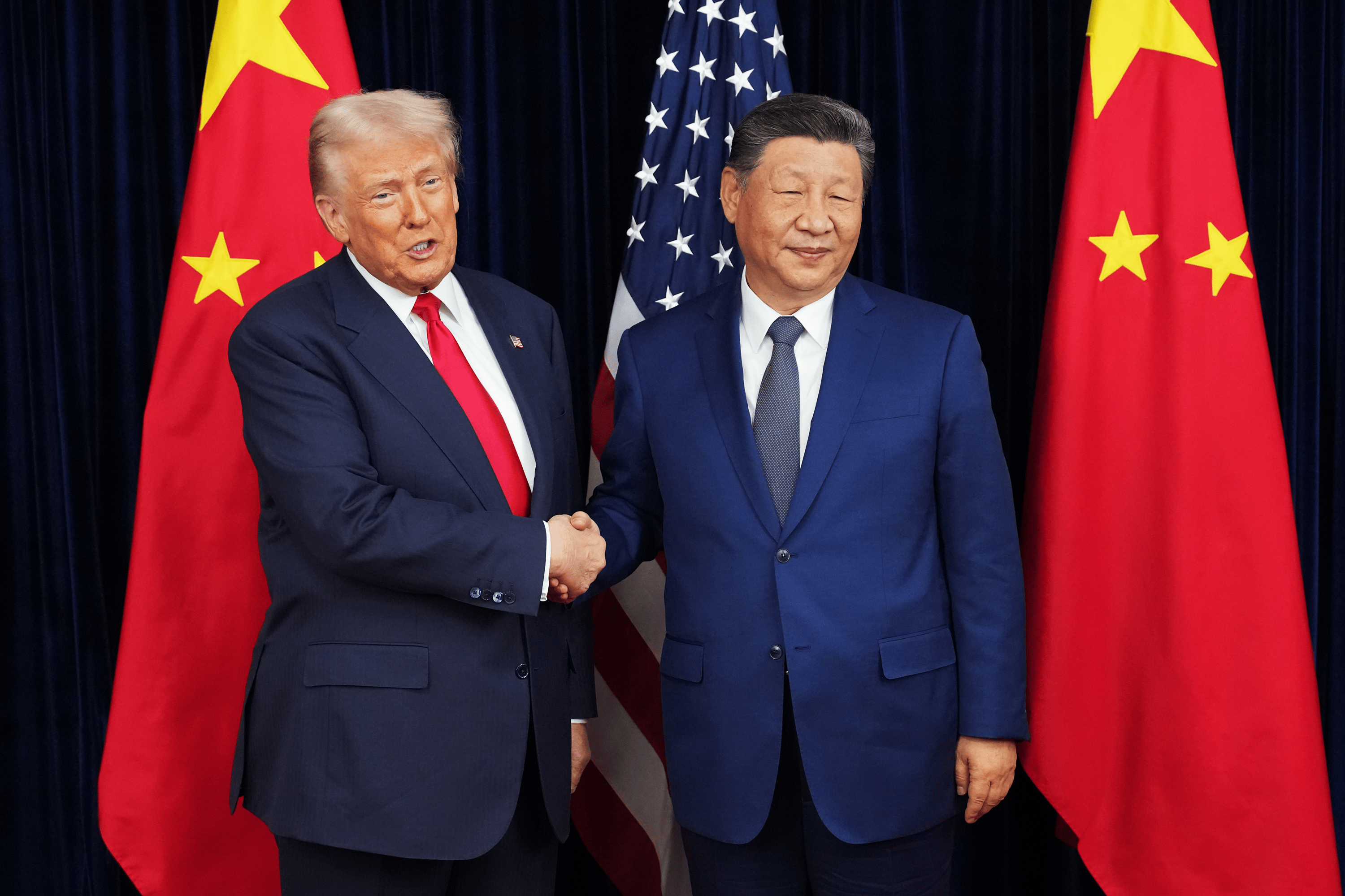

This fall, it will be up to the Supreme Court to decide whether or not many of Trump’s new tariffs are legal. In the meantime, manufacturers across the country continue to navigate evolving trade policy.

On Tuesday, the newest purchasing managers index data will give a better sense of how U.S. manufacturers are fairing more broadly. But for now, we’re going to zoom in a bit on how certain regions of the country are doing, by calling up some regional federal reserve economists.

Starting in New York state, where a lot of durable goods, like metals and machines are manufactured: “We saw a bump up in activity, which was pretty unusual,” said Rich Deitz at the New York Federal Reserve

He said while the New York Fed’s survey showed continued negativity around tariffs, “there's a little bit more activity for some domestic manufacturers because of the higher tariffs, making it more expensive to buy goods from other countries.”

Further south, around the Carolinas and Virginias, where they produce a little bit of everything from autos to chemicals, Jason Kosakow at the Richmond Fed said things are still pretty soft.

“A lot of firms are not necessarily positive right now, but they do have a little bit of hope about the next six months,” he said.

He said input costs have spiked for manufacturers, who are hesitant to pass on costs to customers.

“Food, manufacturing, furniture… they're getting a lot of pushback from retailers, saying, ‘We can't increase prices anymore,’” Kosakow said.

Further west, in the Kansas City Fed district where there’s a lot of meatpacking and HVAC manufacturing, Oklahoma City branch executive Cortney Cowley said firms are absorbing price increases through the supply chain.

“So a supplier taking on some of those, the manufacturer taking on some, and then passing through, you know, another portion of that to the customer,” she said. “We haven't really seen as as maybe as much price pass through to this point.”

And further south, where there’s a lot of food and metals manufacturing and refining, the Dallas Fed’s Emily Kerr said pricing is also a struggle.

“They're not in the best position to say, 'Hey, our costs are going up, so we're going to push those costs through to our customers,’” she said. “I think they've got to be more careful and seeing whether demand can hold up to those higher prices.”

But August’s survey did have good news: New orders turned positive, showing strength in demand.