How a Texas-based manufacturer is dealing with tariff back-and-forth

The extended tariff deadline doesn’t help with planning certainty.

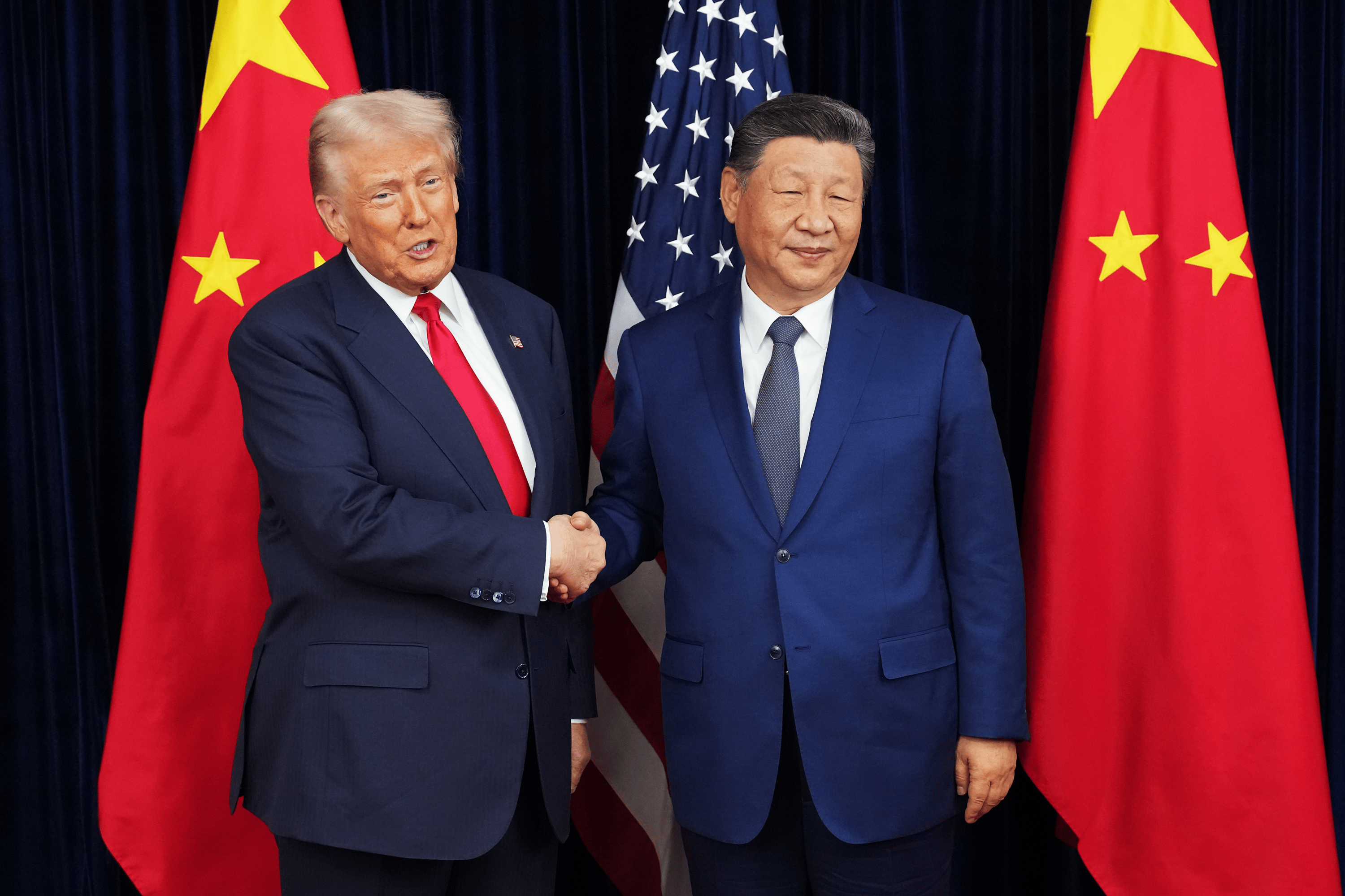

Tuesday was supposed to be the day when U.S. tariffs on Chinese goods were set to go back to sky-high rates of 145%, but President Donald Trump has now extended the truce for yet another 90 days as the U.S. and China hammer out a deal.

That means that, as of now, most Chinese imports to the U.S. face a 30% tariff here, and American exports get taxed 10% in China. None of the back-and-forth is allowing for much certainty for manufacturers that rely on supplies or goods from China.

Sabri Ben-Achour: You've been following U.S. manufacturers — one in particular, since tariffs peaked at 145% in May and then have come down. What is his reaction to the news?

Jennifer Pak: Well, confusion. Ninety days is just too short to plan. This company, called Isotherm, is based in Texas, and it manufactures equipment for chicken plants, commercial fisheries, basically any industry that requires cooling. Here's the company's founder, Zahid Ayub.

Zahid Ayub: Ninety days mean nothing, actually. Our deliveries are more than 90 days, fabrication and shipment.

Pak: Add on the time it takes to get their key material, which is titanium that they get all from China — that's another month or so. So that makes it very hard for them to put a price on things, because it could be different from when they quoted it to when it arrives at their customer's place.

Ben-Achour: When you first spoke to him in Shanghai during a trade show, he told you he was thinking of moving operations out of the U.S. Why and to where?

Pak: He was thinking of Mexico or China. He did this because of the tariffs. The key raw material is titanium, and he can't get that anywhere else. So he thought he would keep his Texas factory for his U.S. clients, but then for his export market, he was thinking of having his products made entirely in China or China and Mexico.

Ben-Achour: So moving production out of the U.S., that is the opposite of what President Trump had in mind. He wanted to bring back manufacturing to the U.S. Could he not just switch suppliers?

Pak: Mr. Ayub says he can't find the titanium tubes and plates that he needs in the U.S. right now. It takes years to get those certifications, and his Chinese supplier has it.

Ben-Achour: How is his business doing right now amid all this sort of flux?

Pak: Mr. Ayub says that he's still importing as usual, the titanium from China. He's mostly absorbing the extra costs, which he says is doable because he had pretty high profit margins. I asked Mr. Ayub what it's been like for him these past 90 days.

Ayub: Honestly, I'm not even paying any more attention to the tariffs and all those things. It's so uncertain. And plus, what can we do? We cannot do much.

Pak: So for now, he says it's still a wait-and-see approach.