Ford Motor working on recyclable car interiors

TEXT OF STORY

Kai Ryssdal: Trucks and SUVs lifted Ford’s fortunes today. Specifically, Ford’s U.S. sales. They were up more than 9 percent last month, as consumers chose bigger, more macho-looking vehicles. For years, the auto industry’s been a man’s world. Still is, to a large degree.

But Marketplace’s Sarah Gardner visited Ford recently and discovered a research team that’s entirely female. The Biomaterials Group is trying to make the interior of Ford’s cars and trucks more recyclable — everything from the cup holders to the seat cushions.

Group of women: My name is Shannon Bollin. My name is Patti Tibbenham. My name is Angela Harris. My name is Ellen Lee. My name is Debbie Mielewski, I’m the technical leader, plastics research at Ford.

Sarah Gardner: Meet Ford’s “Material Girls,” as one of their colleagues affectionately dubbed them. This all-female team of engineers has three Ph.Ds, five master’s degrees, eight Ford vehicles and seven children between them. All but one are Michigan natives, including team leader Debbie Mielewski. She didn’t set out to hire just women, but many are gravitating to environmental sciences, says team member Ellen Lee.

Ellen Lee: Especially in those having to do with materials and things that you can kind of touch and can get hands on.

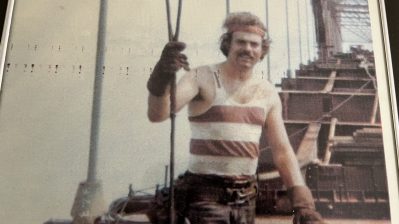

Team leader Debbie Mielewski comes from a hands-on family. Her dad welded parts on a Chrysler assembly line for 40 years; Mielewski’s been at Ford now for 25.

Debbie Mielewski: When you’re young, you think the whole world’s open, I’m going to move to wherever the best job for me is and I’m going to be somewhere warm and then, you just fit in like a glove.

Mielewski’s driving me around Ford’s hometown of Dearborn, just outside Detroit. We’re in a 2011 Ford Flex. It looks like a cross between an SUV and a station wagon and boasts two bio-materials her team helped bring to market.

Mielewski: So here’s the bin; it’s hard to get to…

Mielewski points to a built-in plastic storage bin back in the third row. It’s been partly reinforced with wheat straw instead of glass fiber. Using the waste from a wheat harvest takes a lot less energy than making glass fiber. Wheat straw’s also lighter — and a lighter car helps fuel efficiency. And then, there are the seat cushions, backs and headrests: They’re filled with foam made from soybeans instead of petroleum.

Mielewski: So Ford is currently saving about three million pounds of petroleum each and every year by using soy instead of petroleum.

Ford now uses soy foam seats and backs in almost all of its models, including the Focus and its bestseller, the F-150 pickup. Mielewski admits the real game changer for cars is replacing petroleum as fuel. But she insists every bit helps.

Team member Patti Tibbenham says for years the industry used plastic with abandon.

Patti Tibbenham: Y’know, the raw materials were so cheap that was just what was used, the plastics that were available.

That was true a decade ago, when Mielewski first started pushing bio-plastics at Ford.

Mielewski: We would be invited to a meeting once and then we never got invited back. Because when we pitched these things, people were like, “REALLY, really? We’re not puttin’ that in a car.”

But as oil prices started rising, bio-plastics got Ford’s attention. Mielewski’s team now tests out all sorts of stuff to make car interiors — coconut hair, prairie grass, rice hulls, even old currency. But if the material can’t pass a slew of company standards — cost, safety, durability, odor, aesthetics — it won’t appear in a Ford vehicle.

Team member Angela Harris hands me a shiny fabric sample for a car seat. Seemed good to me.

Gardner: So you’re telling me this, right here, is made of corn?

Angela Harris: Yes.

Gardner: What’s preventing that from going into Ford cars right now?

Harris: So for this particular material, it is a durability issue.

High heat and humidity can make the material crumble. So, this one goes back to the lab. It took six years to get the soy foam seat cushions to market. The first ones they cooked up smelled like rancid popcorn. Harris says the goal is to make these bio-fabrics last a car’s lifetime, but then quickly degrade in a landfill.

Harris: That’s the silver bullet. That’s the Holy Grail we’re trying to work for.

So, a compostable, petroleum-free car? Probably not in their lifetimes, says the team. They’re just happy to drive the research forward, while helping each other through the life’s usual mechanical breakdowns.

Lee: If someone has to pick up a sick kid early, one of us can cover for the other and we kind of understand those things.

Mielewski: It’ll be happening to me tomorrow, is what you’re saying. If your kid’s sick today, mine’s sick tomorrow.

Lee and Mielewski laugh

In Dearborn, Mich., I’m Sarah Gardner for Marketplace.

There’s a lot happening in the world. Through it all, Marketplace is here for you.

You rely on Marketplace to break down the world’s events and tell you how it affects you in a fact-based, approachable way. We rely on your financial support to keep making that possible.

Your donation today powers the independent journalism that you rely on. For just $5/month, you can help sustain Marketplace so we can keep reporting on the things that matter to you.